Digital Transformation – Revit – Voyansi

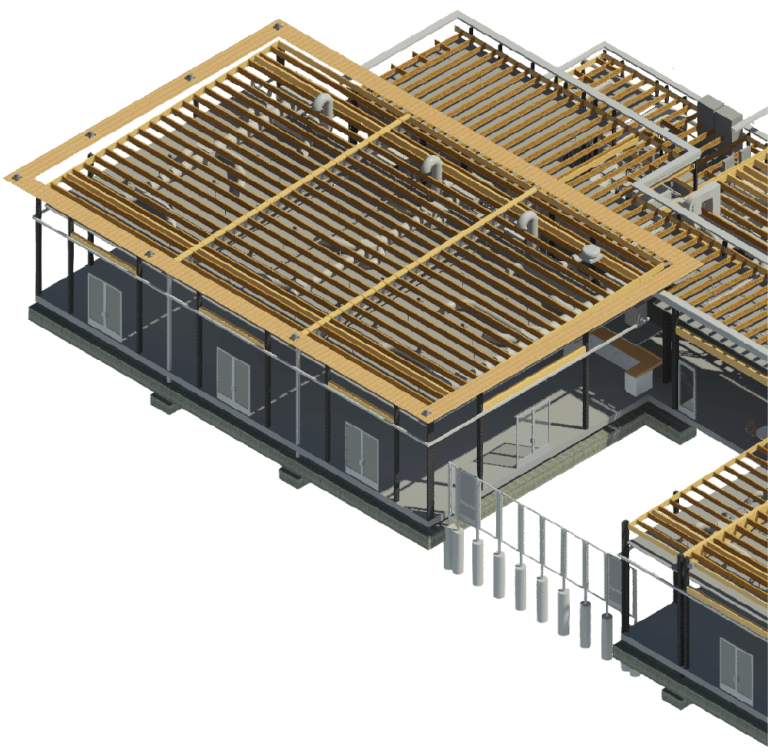

RedBuilt and Voyansi partnered together to create a story of digital transformation.

Off-site construction is an overarching term for the planning, design, fabrication and assembly of building elements at a location other than their final installed location. This supports the rapid and efficient construction of a permanent structure, according to the Off-Site Construction Council.

To build on that:

Prefabrication is the assembly of building systems and components before integrating them into the structure.

Though similar, the difference between prefabrication and modular construction is that the latter refers to complete rooms or sections of a structure that are built in a factory.

Big-name brands have made significant investments in this building method.

For example, Marriott International announced in 2017 that they would use modular construction in 13% of their North American hotel deals that year.

For good reason, the benefits are well-known at this point.

The Modular Building Institute identified nine advantages.

A 2020 report from Dodge Data & Analytics outlined the benefits and impact of prefabrication and modular building. It collected data from a collection of architects, engineers, general contractors, construction management, modular builders, and trade contractors — totaling 608 qualified responses.

The benefits largely reflected those listed above — improved productivity, improved quality, increased schedule certainty, improved cost predictability, reduced waste generated by construction, increased client satisfaction and improved safety performance.

Forecasts for the next three years indicated the most likely building types will be prefabrication in modern construction. These are the results from most likely to least:

The practice is growing, but the adoption rate has been slow and intermittent due to industry perception.

Why? Many cite a simple phrase: we’ve always done it this way. Changing mindsets and operations can be difficult in traditional settings.

Dodge Data & Analytics indicated the top obstacles preventing future use of both prefabrication and modular construction, and sorted the impact on decision-makers from most to least.

Factors preventing prefabrication:

Factors preventing modular construction:

Despite some uncertainty here and there, it’s gripping marketplaces.

A 2019 McKinsey report on modular construction highlighted that demand will be driven by labor and housing shortages — e.g. Australia, UK, Singapore — and the U.S. West Coast.

The field has the potential to deliver $22 billion in annual savings for the European and U.S. markets, and could scale to an industry that represents about $130 billion in US and European real estate by 2030.

“Modular projects likely to deliver the greatest cost savings are those that have the highest proportion of labor-intensive activities and the greatest levels of repeatability,” the firm said.

Market dynamics are one thing. Conversations are another.

Talk to us about it. Our technical representatives can speak to how we’re approaching tailored solutions in prefabricated wall panels and offsite construction.