Trusses used in design for innovative food bank

DETAILS

INDUSTRIES:

PROJECT:

Hopelink Redmond Integrated Service Center

LOCATION

Redmond, Washington

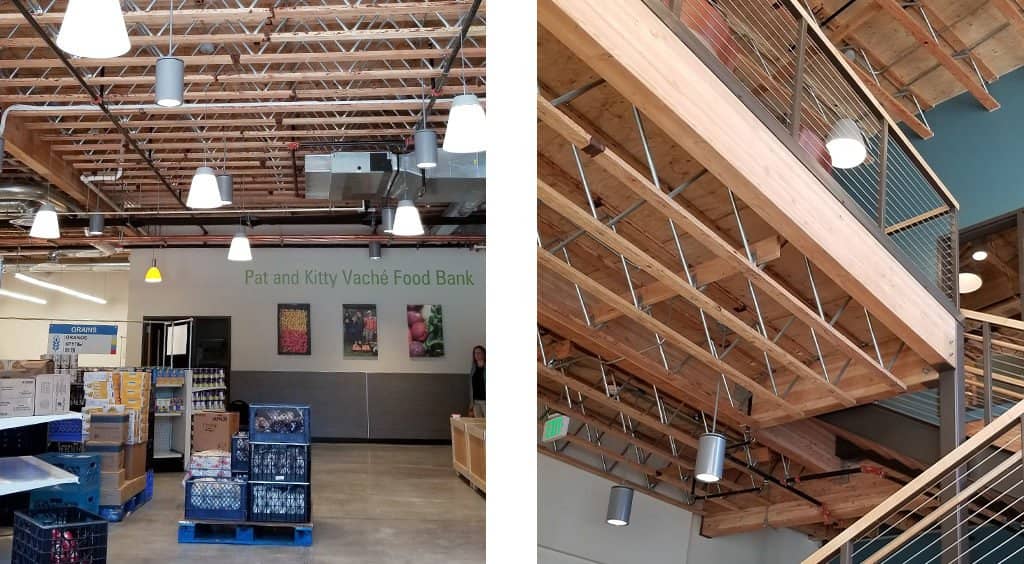

Open web trusses create a warm, welcoming environment

It’s difficult to see where the framework of society starts and ends, but there’s one common foundation wherever you go:

People.

How do you build a community? You start with your neighbors, as Hopelink set out to do starting in 1971 with its vision to create a community free of poverty. Its mission is to make lasting change by promoting self-sufficiency in its community members.

The non-profit in Redmond, Washington expanded its services to support that mission and sought to house them under one structure that included a grocery store style food bank, emergency financial assistance, heating/energy assistance, case management, GED classes, English lessons, employment services and financial coaching.

This led to a large-scale construction project in Redmond, Washington to build a 30,000 square-foot, two-story building, which included a large public plaza for farm-to-table gardens. Hopelink’s administrative offices would also be housed within the structure.

Through a variety of pro-bono resources and dedicated teams, the project made its way to completion, but along the way Mary Eun, a technical representative at RedBuilt, helped them tie it together with her expertise in commercial structures.

“The building is focused on the corner of 154th and 90th and presents a highly transparent public facade, emphasizing the role Hopelink plays in the community,” according to Third Place Design Co-Operative‘s design concept narrative. “The two story glazing at the corner allows the pedestrian and vehicular passerby to view the activity within the space at varying scales and levels of interaction.”

The building’s external, structural transparency was matched by its semi-industrial interior, with a warm, inviting aesthetic that included a mixture of metal and wood materials.

As it happens, RedBuilt specializes in the type of product to achieve that design vision, so Eun was invited by structural engineering firm Swenson Say Fagét to provide feedback on design, engineering, framing, installation and building materials.

How open web trusses satisfied design, budget, and environmental needs

Open web roof trusses and LVL wood were selected to satisfy design needs and budgetary constraints.

“At the very beginning of the process, working solely with steel was ruled out for multiple reasons. Besides the high cost of steel, the building owner wanted a warmer feeling with wood, which also fed into the architect’s semi-industrial look when paired with steel,” Eun said. “After design revisions, we shipped one depth of Red-L™ Open-Web Trusses and two different depths of Red-W™ Open-Web Trusses. We also had RedLam™ LVL joists.”

Because RedBuilt services include design drawings and feedback, project managers and teams were able to stay nimble to meet customer approval and building schedules.

“After the shop drawings were out the design continued to change, so we needed to be flexible. They made some changes in the approval drawings at the stair openings and at the mechanical loft,” she said.

Open-web trusses span the building’s ceiling, opening up the space with exposed wood and steel in a style Eun says is distinctly Northwest.

The architect and client decided that wood is more friendly and welcoming to clients using their services, and a semi-industrial look helped build a feeling of going to a grocery store, not a non-profit’s office building.

Abbott Construction‘s supplier tracked sustainability throughout the project to ensure green building practices found their way into the structure.

Notably, RedBuilt products are sustainably sourced, and a designated engineer on staff manages, researches and supports sustainability initiatives. It may not be what comes to mind immediately, but RedBuilt wood construction and Hopelink community services stem from the same values: making structures and society responsible for continued service to the surrounding environment, be it human or otherwise.

RedBuilt worked closely with project stakeholders to secure a LEED letter and validate that environmentally responsible raw materials were used and their manufacturing extraction locations were within 500 miles. The building qualifies for LEED Gold certification.

The LEED letter penned by Christine Richey, PE, LEED AP BD+C, noted that steel components in the project’s open-web trusses contained 25 percent post-consumer recycled content, and within the total product package each piece was provided at lengths to minimize trim waste.

The plant providing the RedLam™ LVL is located in Stayton, Oregon, and 100 percent of the raw materials for the RedLam™ LVL were harvested within a 500 mile radius of the project site, with the furthest being Dillard, Oregon.

The plant providing the open-web trusses is located in Hillsboro, Oregon, and 100 percent of the wood components are harvested within a 500 mile radius of the project site, with the furthest being Elko, BC.

Framers at Hutt Construction met with RedBuilt to ensure truss installation went smoothly, and soon found that the product was simpler to install than the manufactured plated trusses they were used to.

"I heard from the framer that people who were officed nearby the site saw how smoothly the project went, and it ended up creating more positive business relationships for the framer."

Months of design and project collaboration from RedBuilt lended to an environmentally and financially responsible structure for all involved.

The impact a building can have on its community

The trusses and laminated veneer lumber supported the building’s need to be warm, welcoming and comforting for community members seeking assistance from Hopelink.

The project broke ground in April of 2017 and the structure now stands in Redmond, projected to be annually serving 5,000 clients in the location by 2020. Hopelink helped 63,000 people in 2018 alone within King and Snohomish counties through a variety of programs created to address poverty.

The food bank will contribute to food and nutrition efforts within Hopelink’s Theory of Change, which prepares individuals and families with resources and courses designed to build stability that equips them to exit poverty.

As it stands, last year 2,230,884 meals were provided to 13,998 clients with 240,741 pounds of fresh produce collected for distribution at Hopelink-affiliated food banks, which the urban gardens near the structure support.

RedBuilt teams are grateful to help play a role in structures like this, creating long-lasting community impact through design services, project feedback and sustainable products.

RedBuilt products used in the Hopelink Redmond Center

Learn more about each of the specified products in the project:

CREDITS

ARCHITECT

Third Place Design Co-Operative

CONTRACTOR

Abbott Construction

ENGINEER

Swenson Say Fagét

FRAMER

Hutt Construction